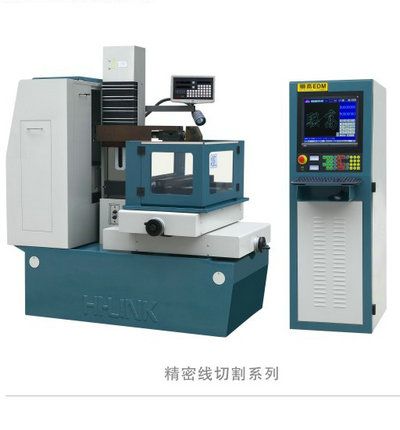

Main features of this series: 1. Adopt the grade linear guide and high-grade ball screw imported from Taiwan, and cooperate with high-strength resin sand casting to ensure the precision of the machine tool.2. Using self-developed discharge pulse power supply, high efficiency, low loss and good finish.3. When the cutting process is over, the wire drum will automatically stop to the right, which is convenient for the upper and lower molybdenum wires.4. After cutting, you can choose to cut off all the power automatically.5. One-way discharge or two-way discharge can be selected to improve the finish.6. The speed of the wire drum can be adjusted by frequency conversion, and the speed can be selected to facilitate the feeding of the wire.7. The wire drum adopts a magnetic induction switch, with no contact commutation, indicating the service life and reducing noise.8. The main shaft is automatically raised and lowered, and the remote control function is used. 9. The grating electronic ruler is used for positioning, and the accuracy is more accurate.Main technical parameters H-CUT-32F H-CUT-40F Worktable size 400*580 680*500 Worktable stroke 400*320 400*500 Cutting taper 400 400 Maximum processing taper ±3 Best surface roughness 0.8u Cutting molybdenum Wire range 0.1-0.22 Maximum cutting speed 200 Cutting accuracy ±5um Dimensions 1600*1000*1850 1800*1250*1950 Machine weight 1600 1900

1. Using slow wire processing technology, multiple processing and repeated cutting.2. The self-developed high-frequency power supply is intelligently controlled by an independent single-chip microcomputer, and the maximum processing speed can reach more than 13000 mm2/H, which is 2-3 times the processing speed of traditional fast wire.The high-frequency power supply of micro-low consumption technology adopts multiple cutting methods to ensure the minimum roughness RA≤0.8μm, which is comparable to the slow wire-feeding machine.3. Self-developed vertical cabinet control cabinet, overall design, plug-in structure, machine tool electrical appliances are placed in the control cabinet, easy to ventilate, heat dissipation, moisture-proof, prolong the life of electronic components, low failure, easy maintenance.4. The computer host adopts industrial computer system platform, dual CPU structure, 320G super large hard disk, and BenQ 17" LCD monitor.